The stone processing industry plays a crucial role in the construction and mining sectors, providing essential materials like crushed stone, gravel, and aggregates for a wide range of applications. One of the most common materials used for construction purposes is mountain stone, which needs to be processed and crushed to meet industry standards. For large-scale operations, the use of a 200t stationary aggregate crusher can significantly boost productivity, but the cost of operating such a plant every day must be carefully considered. In this article, we will explore how the 200t stationary aggregate crusher works, its associated operational costs, and the factors that influence its daily operation in a mountain stone processing setup.

Understanding the 200t Stationary Aggregate Crusher

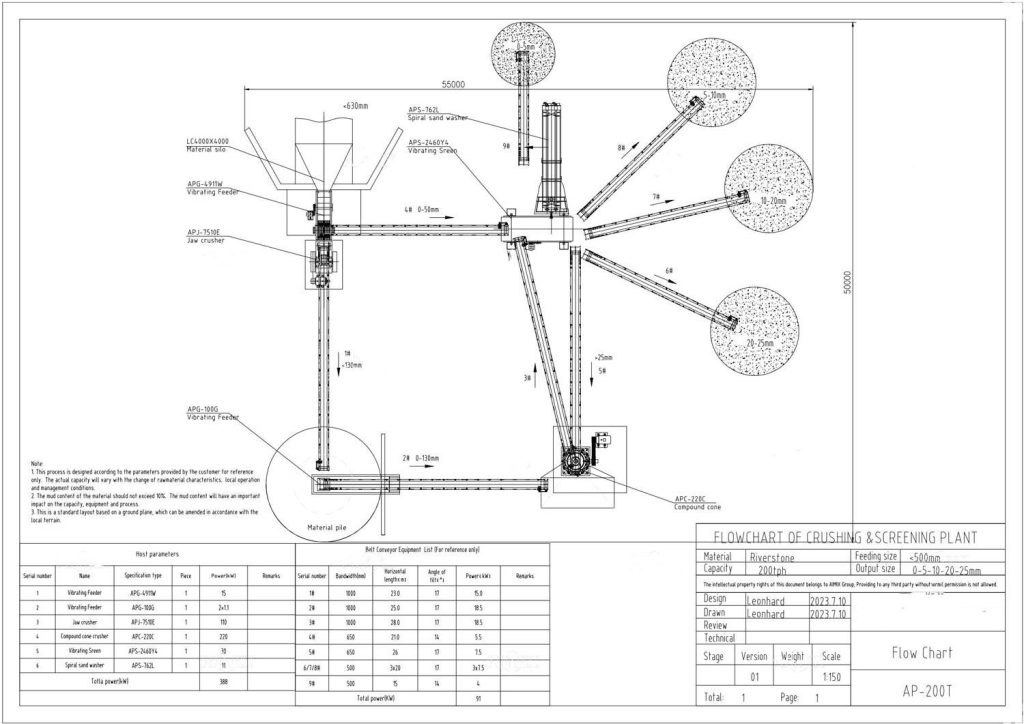

The 200t stationary aggregate crusher is a heavy-duty machine designed for high-capacity processing. It is capable of producing up to 200 tons of crushed aggregate per hour, making it a popular choice for large-scale stone processing operations, particularly in mountainous regions where stone extraction can be more challenging. The machine is typically equipped with a variety of components, including crushers, screens, conveyors, and other auxiliary equipment designed to handle large volumes of material.

In a typical mountain stone processing operation, the 200t stationary aggregate crusher works by breaking down large blocks of mountain stone into smaller, more manageable sizes suitable for use in construction. Depending on the type of crusher used, such as a jaw crusher, cone crusher, or vsi crusher, the final product can vary in size and shape. For example, a vsi crusher is particularly useful for producing finely graded aggregates or manufactured sand, which can be used in concrete mixes.

Key Components of the 200t Stationary Aggregate Crusher

To fully understand the costs associated with operating a 200t stationary aggregate crusher, it is important to consider the key components that make up the system. These components can be divided into several categories:

VSI Crusher Parts: One of the primary components in a stationary aggregate crusher system is the vsi crusher (Vertical Shaft Impact Crusher), which is often used for fine crushing. The vsi crusher parts, including the rotor, bearings, and wear plates, are critical for achieving consistent particle size and high efficiency in the crushing process. These parts undergo significant wear over time and may need to be replaced, which contributes to maintenance costs.

Crusher Aggregate: The crusher aggregate produced by the stationary aggregate crusher consists of crushed rock that can be used in various construction applications, such as road construction, concrete production, and asphalt paving. The type and quality of the aggregate produced depend on the settings of the crusher and the type of raw material being processed.

Screens and Conveyors: After the stone is crushed, it is typically screened to separate different sizes of aggregate. Screens and conveyors are used to sort and transport the crushed material, ensuring that only the appropriate grades are used in construction projects. These components, while essential, also contribute to daily operating costs.

Power Supply and Fuel Costs: Like any large-scale industrial operation, running a 200t stationary aggregate crusher requires a significant power supply. The energy costs for operating the plant can vary depending on the location and the power source used. Diesel generators may be required if the plant is located in a remote area, which could add to the overall operational expenses.

Factors Affecting the Daily Cost of Operating the Crusher

The cost of operating a crusher plant every day depends on various factors. The crusher plant price in peru online is just the initial cost. Understanding these factors will help businesses in Peru and other regions optimize their operations to minimize costs while maximizing efficiency. Here are the main factors that influence daily operating costs:

Material Type and Quality: The type of mountain stone being processed can significantly impact the crusher’s performance and wear rate. Harder stones, such as granite, require more energy and wear-resistant parts, which can increase maintenance costs. Softer stones like limestone are easier to process, leading to lower energy consumption and less wear on the crusher.

Crusher Maintenance: Routine maintenance and replacement of key components, such as vsi crusher parts, are essential to keep the plant running efficiently. Over time, parts like hammers, wear plates, and bearings wear out and need replacement. Regular maintenance can help prevent more expensive repairs down the line, but it also contributes to daily operational costs.

Labor Costs: Labor costs are another significant expense when operating a stationary aggregate crusher. Operators are needed to oversee the machinery, load the raw materials, and maintain the system. In some cases, additional personnel may be required for tasks like quality control, inventory management, or equipment repair.

Fuel and Energy Costs: The 200t stationary aggregate crusher relies on a steady supply of power to run the crushers, screens, and conveyors. If the plant is powered by electricity, the cost of energy will play a major role in determining the overall operating costs. If the plant relies on diesel or other fuel sources, fuel prices in the region will influence daily expenses.

Transportation and Logistics: After the crusher has processed the mountain stone, the resulting aggregate must be transported to construction sites or distribution points. Fuel costs for trucks and transportation logistics will add to the overall daily operating cost.

Calculating the Daily Cost of Operating the 200t Stationary Aggregate Crusher

To get a clearer picture of the cost of operating a crusher plant in Peru, it is essential to calculate the expenses involved in each aspect of the operation. A breakdown of potential daily costs could look like this:

Crusher Parts Replacement: The vsi crusher parts may need to be replaced every few months, but some components may need attention daily due to wear and tear. A replacement for rotor parts or bearings could cost anywhere between \$500 to \$2,000 depending on the part’s specifications and brand.

Power Consumption: Power consumption for the 200t stationary aggregate crusher could be significant, especially if the plant operates at full capacity every day. The cost of power may vary depending on the source (grid electricity vs. diesel generators). For example, if the plant consumes 100 kWh per hour, and the energy cost is \$0.10 per kWh, the total energy cost per day would be \$240 for an 8-hour shift.

Labor Costs: Assuming an average wage of \$50 per day per worker, and requiring about 10 workers for operation, maintenance, and supervision, labor costs would amount to \$500 per day.

Fuel Costs: For a diesel-powered crusher plant, fuel consumption can vary depending on the engine and operation. A 200t crusher plant might consume 50 liters of diesel per hour. At an average cost of \$1 per liter, fuel costs for 8 hours of operation would total \$400.

Maintenance and Repairs: Regular maintenance costs, including part replacements for crusher aggregate production and general upkeep of machinery, might range from \$100 to \$300 per day depending on the frequency of maintenance tasks and the condition of the machinery.

When considering all these factors, the total daily cost of operating the 200t stationary aggregate crusher could range from \$1,000 to \$2,000 per day, depending on the efficiency of the operation and the cost of resources in the region.

The 200t stationary aggregate crusher is an indispensable tool for processing mountain stone and producing quality aggregate for construction projects. However, operating such a plant comes with a significant cost. To manage daily expenses efficiently, it is important to carefully monitor and optimize each aspect of the operation, from vsi crusher parts maintenance to fuel and labor costs. By understanding the factors that affect daily operation and being proactive in maintaining equipment, businesses can keep costs down while maximizing output and profitability. Ultimately, investing in a well-maintained crusher plant will pay off through increased productivity and long-term success in the stone processing industry.